Menu

Menu:

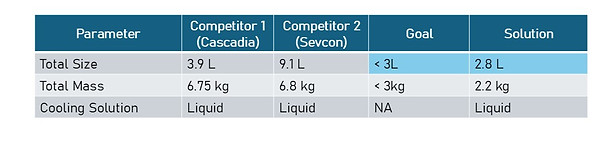

Overall Team Goal: create a smaller, lighter and more efficient traction inverter (motor controller for EVs) than industry.

-

Completed for fourth year design project

-

Team of four:

-

Me: mech for HV thermal components (design, analysis, manufacturing, validation)

-

1 software

-

1 electrical + controls

-

1 mechanical for exterior + mounting

-

-

Timeline: September 2023 – March 2024

Results

Assembly Level Design

Thermal Requirements

-

18 MOSFETs generating around 200W heat

Thermal Solution Overview

Thermal Design Summary

Why Liquid Cooling?

-

Air cooling assy was too large – the team decided that the size was the most impressive part of the inverter

-

Decided using heat sink specs:

-

1 large heat sink: 𝑅_𝑡ℎ = ∆𝑇/𝑄 = ((60−25)℃)/200𝑊

-

18 small heat sinks: 𝑅_𝑡ℎ = ∆𝑇/𝑄 = ((60−25)℃)/11.11𝑊

-

Cold Plate Overview

Material Selection

Coolant

-

Water:

-

Low viscosity

-

Good thermal properties

-

Cold plate

-

Al 6061:

-

Will not corrode

-

Good thermal properties

-

Fasteners

-

Zinc plated steel:

-

Will not corrode

-

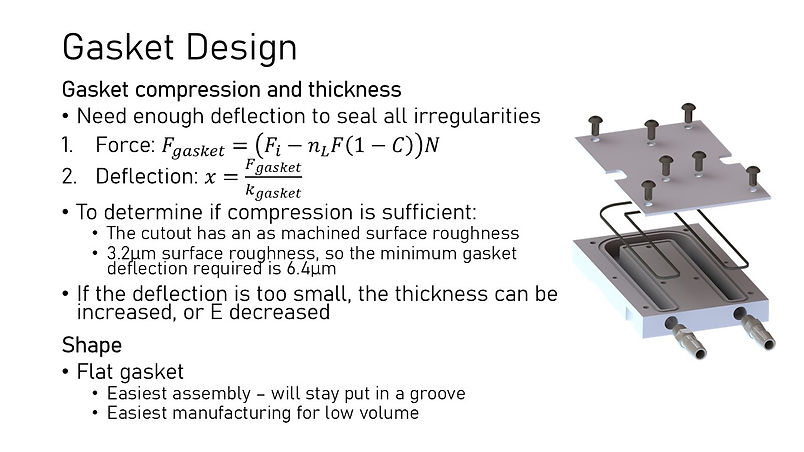

Gasket

-

Silicone rubber, 60A hardness:

-

High melting point and low freezing point

-

Fittings

-

PVC:

-

Low pressure and moderate temperature application

-

Will not corrode

-

Considerations for hotter/colder operating temperatures

-

Consider if coolant will boil/melt

-

Consider if gasket material will melt/freeze or become brittle

Thermal Validation Summary

Using ASTM D5470:

-

Copper block simulates heat from MOSFETs.

Thermal Validation Results

-

Maximum simulation temperature is 34C (25C coolant temp)

-

Maximum real-life temperature will be less that 36C (25C coolant temp)

Manufacturing Processes

Cold plate

-

Base: CNC mill

-

Lid: water jet

Gasket

-

Cut with scissors

-

Could also be laser cut or purchased

Busbars

-

Water jet then hand bent

Busbar Design

Manufacturing Improvements

-

Cold plate base can be created with a 3 axis CNC

-

Fittings moved

-

Thicker lid allows for counterbores

-

-

High volume manufacturing

-

Cold plate can be cast

-

Use fittings with a quicker assembly

-

Busbars can be stamped

-

Gasket can be punched

-

Shape:

-

Busbars kept as short as possible to decrease losses, mass and EMI generation

Material:

-

Copper 110 (good electrical conductivity and workability)

Sizing:

-

Ampacity is dependent on cross sectional area

-

Current: 𝐼=𝑃/𝑉 𝑥 𝑆𝐹=(30 000𝑊)/600𝑉 𝑥 1.5=75𝐴

-

Dimensions are decided using standards found in literature for the given current: 12.7mm x 1.5875mm

Improvements:

-

Laminate the bus bars to decrease risk of EMI interference

(busbars were created by another group member)

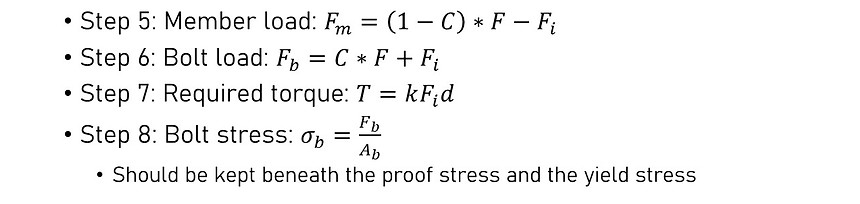

Bolted Joint Design

Goals:

-

Ensure the gasket is compressed enough to seal

-

Ensure the assembly can withstand the internal force due to the coolant pressure

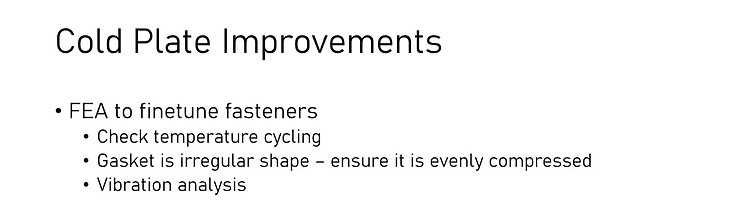

Cold Plate Improvements

Gasket Design

Exterior Improvements

Traction Inverter + Cold Plate

2023 - 2024